ERP for Blast Curtain Manufacturing

Custom ERP Development

Sneak Peek

Anadea team developed an ERP system for a manufacturer of life-saving physical security products. The resulting product is a comprehensive solution for order management, customer relationship management, as well as inventory, manufacturing and supply chain management.

Story Behind

The customer is an owner of a company that designs and manufactures "blast curtains." These curtains protect people from glass shards during an explosion. Blast curtains ensure ballistic, frag, fire and blast protection while safely capturing deadly flying particles.

The customer was looking for an experienced ERP development company because their business required a custom specialized software to manage orders, track inventory, and coordinate with third-party manufacturers. At this stage, we came onboard and started building a comprehensive ERP system.

Anadea Team Work on ERP

The project was launched in two stages. The first stage covered customer relationship management capabilities and a functionality to perform calculations and quotations. Manufacturing and outsourcing management functionality was released during the second stage. The following functional areas were implemented:

Customer relationship management

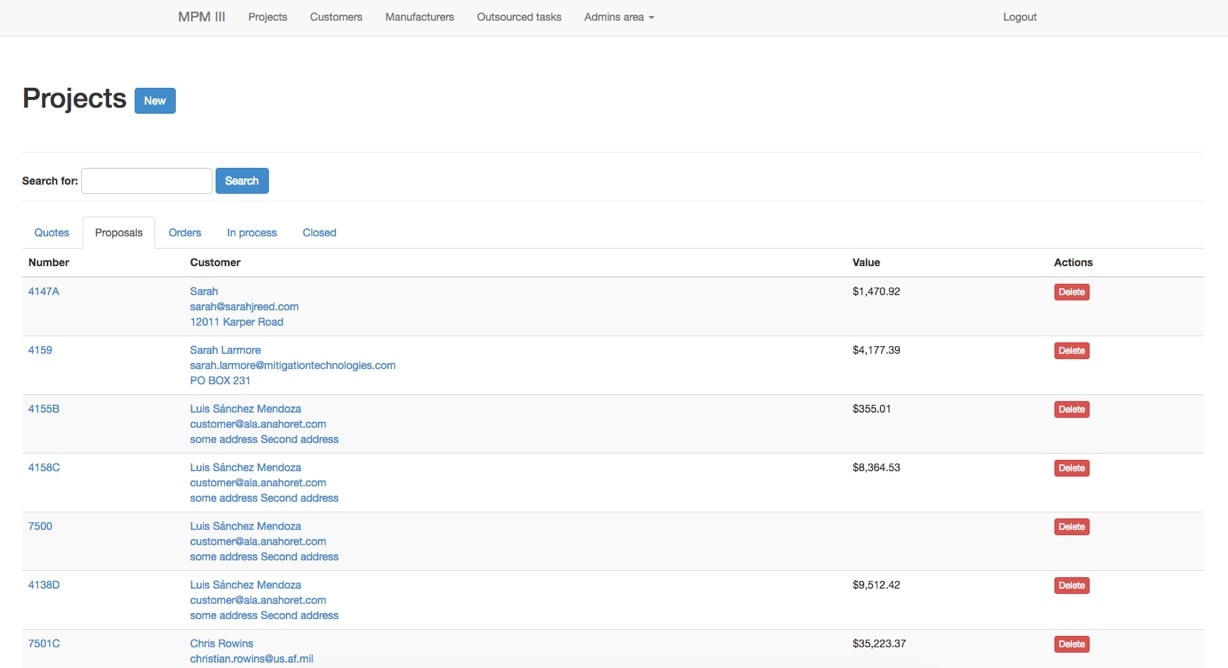

The system tracks all interactions with customers and monitors order status.

Project management

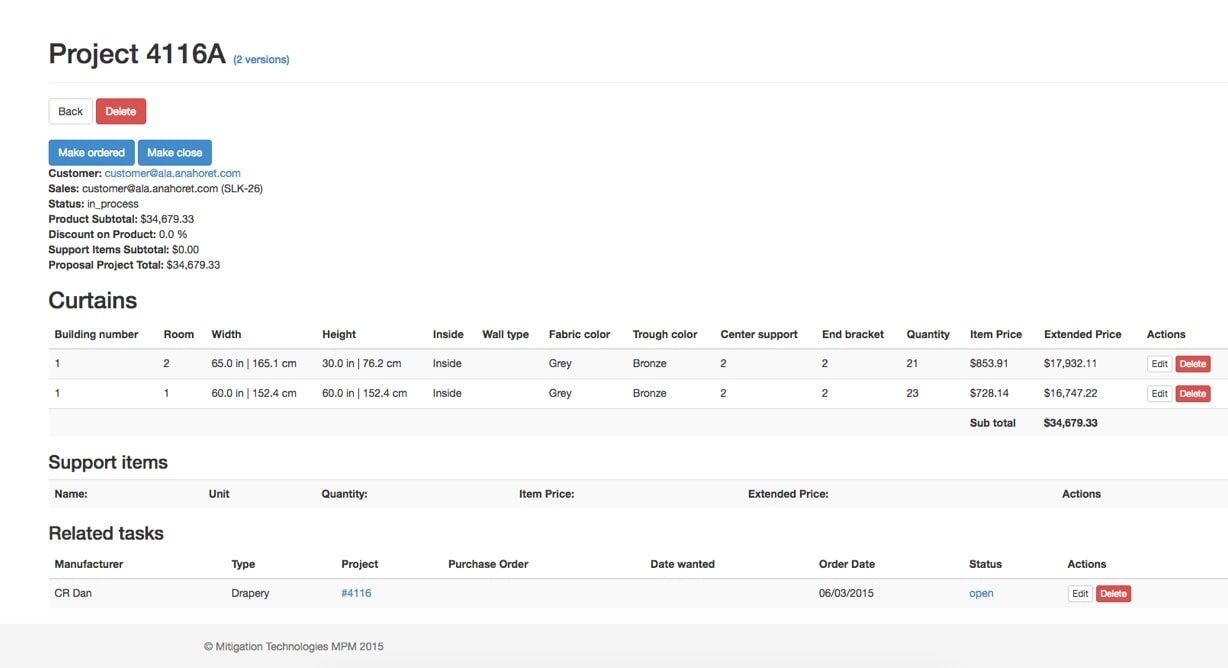

- The new project is created for each new or returning customer.

- The project contains settings that enable accurate quotations.

- The manufacturing manager creates outsourced tasks that are required to produce and deliver the order. The outsourced tasks are added to the quotation.

Price management

Price settings required to generate the quotation can be customized in the admin area.

Order management

- After a project has been approved, the order status gets updated. This allows to easily monitor the status of the order.

- The stock gets updated based on the inventory required to produce the order.

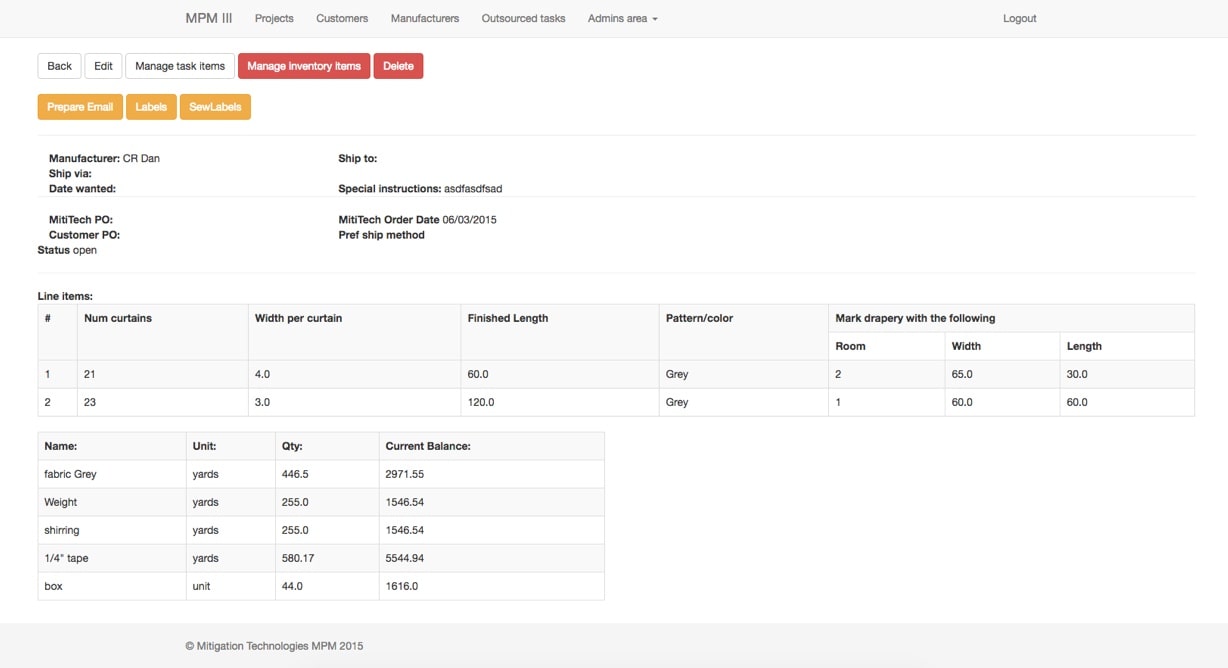

- If some parts of the order are supplied by third-party manufacturers, unique labels with product specifics are generated, printed, and sent to these manufacturers.

Inventory management

- Company managers can monitor stock inventory and add inventory to the stock so that the system could write it off automatically.

- The inventory is manufacturer-specific: every third party responsible for specific parts of the product tracks its own inventory.

Manufacturing and task management

After the “In progress” status has been assigned to the project, all parts and associated outsourced tasks can be easily tracked in one place.

Project versioning

A project could go through multiple versions which change the final costs and settings. The company manager could track all versions in the project.

At the end of the manufacturing cycle, the company manager receives the end-product ready to be packed according to the packaging instructions. The product is sent to the customer and marked as closed.

Testimonials

Challenges

The main challenge of this project was the procedure. The close collaboration with the customer allowed for clear understanding of the workflow specialties. Quote calculations can become very complex, and our team managed to make them flexible by implementing a kit of settings which enabled the user to change the general aspects of calculations.

The manufacturing labels generation was another important functionality that had to be approached with special care. The specifications required the generation of PDF files auto-populated with order-specific content and other details. The content was formatted according to Avery standards and included the information required to accurately deliver the right parts of the order.

The ERP system allowed the use of both the metric and the US standard systems. Depending on the client's geographic location or personal preferences, the administrator could use either measurement system for quotation and order processing.

Services &

Technologies

Back-end development

Project management

Technology stack

Ruby on Rails, PostgreSQL, Twitter Bootstrap, jQuery

More than just a solution

We developed a highly customized feature-rich ERP solution. After the core functionality was implemented, the application went into production. It took three months to launch the two releases, and the project owner started using the fully working application.

The system has been extensively used by the client company. At the next stage, the code was handed over to the client’s in-house developers. We continue to provide on-demand consultations to the client.

Contact us

We are excited to hear your idea and we are always open to discuss it! Tell us a bit more about you and the project you have in mind.

Send us your request for proposal, and we'll reply with the estimate.